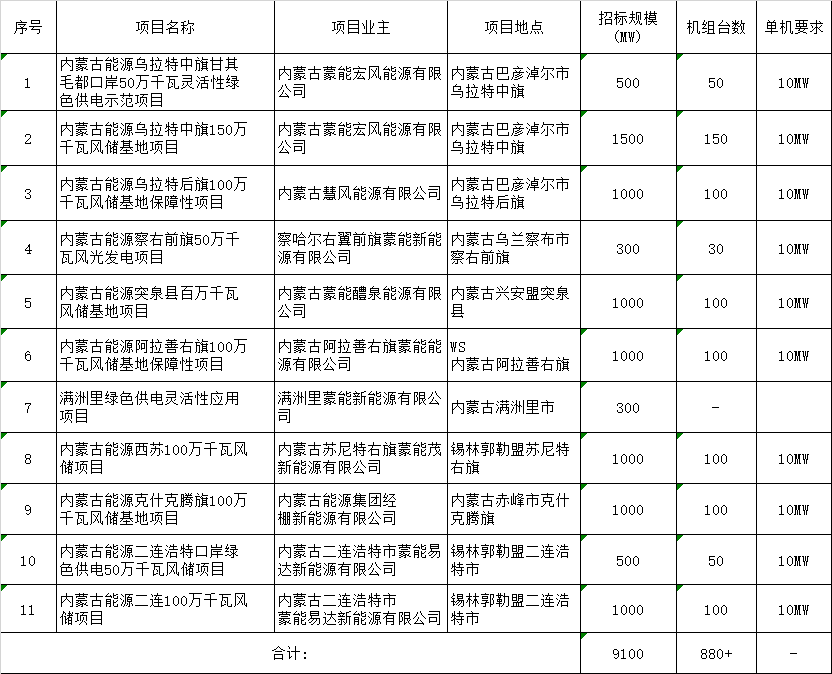

9.1 million kilowatts, 880+units! Continuous bidding for 10MW wind turbines!

Recently, Inner Mongolia Energy Group has continuously issued bidding notices for 11 EPC general contracting projects, including the 500000 kW flexible green power supply demonstration project at Ganqimao Port in Urad Middle Banner of Inner Mongolia Energy, the 1.5 MW wind storage base project in Urad Middle Banner of Inner Mongolia Energy, and the 1 million kW wind storage base guarantee project in Urad Back Banner of Inner Mongolia Energy. The total wind power scale is 9.1 million kW, and more than 880 10MW wind turbines have been purchased.

1. Inner Mongolia Energy Urad Middle Banner Ganqi Maodu Port 500000 kW Flexible Green Power Supply Demonstration Project EPC General Contracting Project Bidding Announcement

Tender number: HNZB2024-02-3-097

1. Bidding conditions

The EPC general contracting project of the 500000 kilowatt flexible green power supply demonstration project at Ganqimaodu Port in Inner Mongolia Energy Urad Middle Banner has been approved by the project approval authority. The project funds are self raised by the bidder and bank loans, and the bidder is Inner Mongolia Mengneng Hong Wind Energy Source Co., Ltd. The bidding agency is Huaneng Tendering Co., Ltd. This project has met the bidding conditions and is now open for bidding for the EPC general contracting project.

2. Project Overview and Bidding Scope

2.1 Project Overview:

The site of the 500000 kilowatt flexible green power supply demonstration project at Ganqimao Port in Urad Middle Banner is located in Urad Middle Banner, Bayannur City, Inner Mongolia Autonomous Region. The construction scale of this project is 500MW, and it is planned to be completed and put into operation in 2024. The wind farm construction includes 50 wind turbines with a rated power of 10000kW, and each wind turbine is equipped with one box type substation. A new manned 220kV boosting station will be built for the project, with two units of 250MVA capacity. Two levels of voltage boosting stations, 220kV and 35kV, will be connected to the 220kV side of the Bazhong 500kV substation through a single 220kV line; The length of the line is 20km. The wire models are JL/G1A-2 × 400220kV, and the distribution device adopts GIS prefabricated compartment type. The energy storage part of this project is temporarily designed according to electrochemical shared energy storage, with a capacity of 100MW/200MWh

The final access system plan for this project is subject to the access system review minutes.

2.2 Scale: The construction capacity for this phase is 500MW, including the construction of one 220kV booster station and supporting facilities such as an operation management center. The energy storage capacity is 100MW/200MWh.

2.3 Construction location: Within the territory of Urad Middle Banner, Bayannur City, Inner Mongolia.

2.4 Construction period requirements: The plan is to start construction on April 15, 2024 (the specific start date shall be notified by the tenderer or supervisor), and the full capacity grid connection conditions will be met by November 16, 2024.

2.5 Scope of bidding:

This project is an EPC general contracting project, and the contractor is responsible for the scope of engineering bidding: all survey and design, equipment and material procurement, engineering construction, installation and commissioning, testing and acceptance (including government and special acceptance), smart wind farm design and construction (including full coverage of 5G networks in booster stations and equipment areas), compliance procedures (detailed delineation of boundaries), and external coordination related to the project. Even if it is not specified in the bidding scope, it has been proven that it is necessary to ensure the power generation and operation of the project and is still within the scope of work that the contractor should undertake.

The specific bidding scope includes but is not limited to the following content:

(1) Survey and Design: Design and management work for wind farms, maintenance roads, 35kV collection lines, manned 220kV booster stations, access roads, construction roads, and reactive power topics, including survey and surveying (including test piles and testing, issuing testing reports), micro site selection review, preliminary design, preliminary design estimate, execution estimate, construction drawing design, construction drawing budget, completion drawing publication and settlement, equipment on-site technical services, etc. The design must be approved in writing by the employer for implementation. The contractor is required to complete technical disclosure, design representative, dispatch design representatives to the site to solve technical problems related to design during construction, as well as dynamic design work based on site terrain and land acquisition adjustments, and all work related to the full capacity grid connection and completion of this project. The contractor shall not modify the feasibility study or preliminary design plan of the project without authorization. In case of technical changes, the change plan must be approved in writing by the supervisor and the employer before implementation.

(2) Equipment and material supply: The contractor is responsible for the procurement and transportation of complete sets of wind turbine power generation equipment, box transformers, towers, wind turbine foundation anchor plates and bolts (if any), cables (including optical cables), cable terminal (middle) joints, 35kV collection lines, manned 220kV booster stations, SVGs, network related equipment (including but not limited to wind power prediction equipment, etc.), computer monitoring and protection, communication, communication, and measurement equipment required for the entire project. The contractor is responsible for the unloading, secondary transportation (including yard), on-site and outdoor transportation, storage, management, and handover of all equipment and materials for this bidding project.

(3) Construction and Installation Engineering: The contractor is responsible for all civil engineering, installation, and commissioning work within the scope of the project (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station), and is responsible for cooperating with a third party commissioned by the tenderer to carry out various inspections, tests, and inspections of the project. The contractor is responsible for individual and system debugging and startup trial operation of the project, and is responsible for the acceptance work of local relevant departments, power quality supervision departments, and power grid companies (including project installation and grid connection procedures). The contractor is responsible for the implementation of environmental protection measures, water conservation measures, occupational assessment and safety assessment measures, environmental protection and environmental impact assessment, fire protection, lightning protection, flood prevention, and other scheme design, implementation, and acceptance, as well as other special acceptance work (detailed boundaries are shown in the attached table: the employer and contractor). Responsibility division table). Complete the production and hanging of all equipment identification, safety signs, traffic signs, fire safety signs, and life signs in accordance with national and industry standards, as well as all safety signs and warning lines (including material procurement and compliance with infrastructure and production management standards).

(4) Equipment testing and debugging (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station): including but not limited to fan, box transformer, various specifications of cables, electrical primary equipment system, electrical secondary equipment system, communication system, fire protection system, background monitoring system, video monitoring system installation equipment and protection setting, etc. All equipment and lines within the site are connected to the booster station with "five remote" functions (telemetry, remote signaling, remote adjustment, remote control, and remote viewing) and cooperate with debugging; The performance test of the primary frequency regulation device has passed the power grid acceptance, meeting the remote data transmission requirements of the employer's backend; Third party testing of equipment and materials, calculation of stability control devices and relay protection settings, SVG/performance testing, AVC/AGC performance testing, communication engineering technical services, power quality testing, electromagnetic transient simulation modeling of stations, electromechanical transient simulation modeling, secondary security evaluation, special testing of electrical equipment, network related testing, etc. The grid connection testing services provided meet the relevant requirements of the country, industry, and national power grid.

Responsible for handling grid connection procedures, including but not limited to equipment numbering, line naming, power quality evaluation, protection setting, calibration and acceptance of electricity meters and related equipment, grid connection acceptance of power companies, quality supervision and inspection of power engineering, and obtaining final supervision reports and grid connection agreements, grid connection dispatch agreements, power business licenses, high-voltage power supply and consumption contracts, and purchase and sales contracts. Undertake the review and acceptance related expenses involved in this project.

Responsible for handling administrative licensing documents for project commencement, including but not limited to construction land planning permit, construction project planning permit, construction permit, fire protection design review and filing, etc;

(5) Defect handling and other work caused by the contractor's responsibility during the warranty period.

(6) Responsible for leveling and handling the transportation roads for large items within the project scope.

(7) Responsible for engineering related work that is not specified in the contract but must be completed in order to complete project construction, acceptance, commissioning, and smooth handover of production.

(8) Transportation of large equipment, transportation renovation, expansion, reinforcement, widening, clearing of obstacles, road repair (restoration), leasing of secondary transportation sites, and handling of corresponding temporary land use procedures both inside and outside the construction site, and bearing corresponding costs. Road repair (restoration) needs to be carried out according to the original road standards.

(9) Complete the special approval and acceptance procedures for the project as required, as well as other procedures related to the project. (See Appendix: Division of Responsibilities between the Employer and the Contractor)

(10) Responsible for coordinating and arranging the work of connecting to the central control center during the design, procurement, construction, and acceptance stages, ensuring the rationality, completeness, and comprehensiveness of the integration of various systems and equipment in the station into the central control center. Ensure synchronous operation of the station and the central control center.

(11) Responsible for the construction of a smart wind farm for this project, including full coverage of 5G networks.

(12) Responsible for coordinating and incurring costs for local farmers and herdsmen's obstruction of work caused by construction, transportation, and other contracting parties.

(13) Responsible for the construction of a safety production video monitoring system. This project is equipped with a safety production video monitoring system, and it is required that the safety production video monitoring system has the necessary conditions for use before the commencement of the main project (see Annex "Notice on the Configuration of Safety Production Video Monitoring System in New Energy Infrastructure Projects" Xinneng [2023] No. 15). The data can be uploaded to the Inner Mongolia Energy Group Smart Construction Platform.

(14) The Inner Mongolia Energy Group's smart construction site platform must be used during the project construction process.

Note: In the "Technical Specification Book" of the equipment attached to this bidding document, the tenderer/party refers to the contractor/party of this project, and the bidder/party refers to the subcontractor.

In addition to the clear requirements mentioned above, this includes but is not limited to the survey and design of wind farm areas, manned 220kV booster stations, 35kV collection lines, as well as the procurement and supply of all equipment and materials related to the project, construction and installation engineering, project management, commissioning, trial operation, transfer of production, training, acceptance (including stage acceptance, relevant special acceptance and completion acceptance, etc.), and services during the engineering quality warranty period. The specific bidding scope is detailed in Chapter 6 of the bidding documents, Employer's Requirements.

2. Bid Announcement for EPC General Contracting Project of Inner Mongolia Energy Urad Middle Banner 1.5 million kW Wind Storage Base Project

Tender number: HNZB2024-02-3-096

1. Bidding conditions

The EPC general contracting project of the 1.5 million kilowatt wind storage base project in Urad Middle Banner, Inner Mongolia Energy has been approved by the project approval authority. The project funds are self raised by the bidder and bank loans, and the bidder is Inner Mongolia Mengneng Hongfeng Energy Co., Ltd. The bidding agency is Huaneng Tendering Co., Ltd. This project has met the bidding conditions and is now open for bidding for the EPC general contracting project.

2. Project Overview and Bidding Scope

2.1 Project Overview:

The site of the 1.5 million kilowatt wind storage base project in Urad Middle Banner, Bayannur City, Inner Mongolia Autonomous Region is located.

2.2 Scale: The construction capacity of this phase is 1500MW, including the construction of 3 220kV booster stations and supporting facilities such as operation management centers, 150 wind turbines with a single unit capacity of 10MW, and the energy storage system is temporarily designed based on electrochemical shared energy storage, with a storage capacity of 300MW/600MWh.

2.3 Construction location: Within the territory of Urad Middle Banner, Bayannur City, Inner Mongolia.

2.4 Construction period requirements: The plan is to start construction on March 23, 2024 (the specific start date shall be notified by the tenderer or supervisor), and the full capacity grid connection conditions will be met by November 16, 2024.

2.5 Scope of bidding:

This project is an EPC general contracting project, and the contractor is responsible for the scope of engineering bidding: all survey and design, equipment and material procurement, engineering construction, installation and commissioning, testing and acceptance (including government and special acceptance), safety production video monitoring system, smart wind farm design and construction (including full coverage of 5G networks in booster stations and equipment areas), compliance procedures, and external coordination related to the project. Even if it is not specified in the bidding scope, it has been proven that it is necessary to ensure the power generation operation of the project and is still the responsibility of the contractor. Within the scope of work.

The specific bidding scope includes but is not limited to the following content:

(1) Survey and Design: Design and management work for wind farms, maintenance roads, 35kV transmission lines, 220kV substation with few personnel on duty, 220kV substation with personnel on duty and access roads, construction roads, and reactive power topics, including survey and surveying (including test piles and testing, issuing testing reports), micro site selection review, preliminary design, preliminary design estimate, execution estimate, construction drawing design, construction drawing budget, completion drawing publication and settlement, and on-site technical services for equipment. The design must be approved in writing by the employer for implementation. The contractor is required to complete technical disclosure, design representative, dispatch design representatives to the site to solve technical problems related to design during construction, as well as dynamic design work based on site terrain and land acquisition adjustments, and all work related to the full capacity grid connection and completion of this project. The contractor shall not modify the feasibility study or preliminary design plan of the project without authorization. In case of technical changes, the change plan must be approved in writing by the supervisor and the employer before implementation.

(2) Equipment and material supply: The contractor is responsible for the procurement and transportation of complete sets of wind turbine power generation equipment, box transformers, towers, wind turbine foundation anchor plates and bolts (if any), cables (including optical cables), cable terminal (middle) joints, 35kV power collection lines, few person on duty 220kV booster stations, manned 220kV booster stations, SVGs, grid related equipment (including but not limited to wind power prediction equipment, etc.), computer monitoring and protection, communication, communication and measurement equipment required for the entire project. The contractor is responsible for the unloading, secondary transportation (including yard), transportation, storage, management, and handover of all equipment and materials for this bidding project.

(3) Construction and Installation Engineering: The contractor is responsible for all civil engineering, installation, and commissioning work within the scope of the project (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station), and is responsible for cooperating with third-party inspections, tests, and testing commissioned by the tenderer. The contractor is also responsible for individual and system debugging and startup trial operation of the project, acceptance work of local relevant departments, power quality supervision departments, and power grid companies (including project installation and grid connection procedures). The contractor is also responsible for the design, implementation, and acceptance of fire protection, lightning protection, flood prevention and other schemes, as well as other special acceptance work (detailed boundaries are shown in the attached table: Division of Responsibilities between the employer and the contractor). Complete the production and hanging of all equipment identification, safety signs, traffic signs, fire safety signs, and life signs in accordance with national and industry standards, as well as all safety signs and warning lines (including material procurement and compliance with infrastructure and production management standards).

(4) Equipment testing and debugging (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station): including but not limited to fan, box transformer, various specifications of cables, electrical primary equipment system, electrical secondary equipment system, communication system, fire protection system, background monitoring system, video monitoring system installation equipment and protection setting, etc. All equipment and lines within the site are connected to the booster station with "five remote" functions (telemetry, remote signaling, remote adjustment, remote control, and remote viewing) and cooperate with debugging; The performance test of the primary frequency regulation device has passed the power grid acceptance, meeting the remote data transmission requirements of the employer's backend; Third party testing of equipment and materials, calculation of stability control devices and relay protection settings, SVG/performance testing, AVC/AGC performance testing, communication engineering technical services, power quality testing, electromagnetic transient simulation modeling of stations, electromechanical transient simulation modeling, secondary security evaluation, special testing of electrical equipment, network related testing, etc. The grid connection testing services provided meet the relevant requirements of the country, industry, and national power grid.

Responsible for handling grid connection procedures, including but not limited to equipment numbering, line naming, power quality evaluation, protection setting, calibration and acceptance of electricity meters and related equipment, grid connection acceptance of power companies, quality supervision and inspection of power engineering, and obtaining final supervision reports and grid connection agreements, grid connection dispatch agreements, power business licenses, high-voltage power supply and consumption contracts, and purchase and sales contracts. Undertake the review and acceptance related expenses involved in this project.

Responsible for handling administrative permit documents for project commencement, including but not limited to construction land planning permit, construction project planning permit, construction permit, fire protection drawing review and reporting, acceptance, etc;

(5) Defect handling and other work caused by the contractor's responsibility during the warranty period.

(6) Responsible for leveling and handling the transportation roads for large items within the project scope.

(7) Responsible for engineering related work that is not specified in the contract but must be completed in order to complete project construction, acceptance, commissioning, and smooth handover.

(8) Transportation of large equipment, transportation renovation, expansion, reinforcement, widening, clearing of obstacles, road repair (restoration), leasing of secondary transportation sites, and handling of corresponding temporary land use procedures both inside and outside the construction site, and bearing corresponding costs. Road repair (restoration) needs to be carried out according to the original road standards.

(9) Complete the special approval and acceptance procedures for the project as required, as well as other procedures related to the project. (See Appendix: Division of Responsibilities between the Employer and the Contractor)

(10) Responsible for coordinating and arranging the work of connecting to the central control center during the design, procurement, construction, and acceptance stages, ensuring the rationality, completeness, and comprehensiveness of the integration of various systems and equipment in the station into the central control center. Ensure synchronous operation of the station and the central control center.

(11) Responsible for the construction of a smart wind farm for this project, including full coverage of 5G networks.

(12) Responsible for coordinating and incurring costs for local farmers and herdsmen's obstruction of work caused by construction, transportation, and other contracting parties.

(13) Responsible for the construction of a safety production video monitoring system. This project is equipped with a safety production video monitoring system, and it is required that the safety production video monitoring system has the necessary conditions for use before the commencement of the main project (see Annex "Notice on the Configuration of Safety Production Video Monitoring System in New Energy Infrastructure Projects" Xinneng [2023] No. 15), and the data can be uploaded to the Inner Mongolia Energy Group Smart Construction Platform.

(14) The Inner Mongolia Energy Group's smart construction site platform must be used during the project construction process.

Note: In the "Technical Specification Book" of the equipment attached to this bidding document, the tenderer/party refers to the contractor/party of this project, and the bidder/party refers to the subcontractor.

In addition to the clear requirements mentioned above, this includes but is not limited to the survey and design of the wind farm area, supporting 220kV booster stations with few personnel on duty, and manned 220kV booster stations, as well as the procurement and supply of all equipment and materials related to the project, construction of building engineering, installation engineering, project management, commissioning, trial operation, transfer of production, training, acceptance (including stage acceptance, relevant special acceptance, and completion acceptance, etc.), and services during the engineering quality warranty period. The specific bidding scope is detailed in Chapter 6 of the bidding documents, including the requirements of the employer.

3. Bid Announcement for EPC General Contracting Project of 1 million kW Wind Storage Base Guarantee Project in Urad Banner, Inner Mongolia Energy

Tender number: HNZB2024-02-3-095

1. Bidding conditions

The EPC general contracting project of the 1 million kilowatt wind storage base guarantee project in Urad Banner, Inner Mongolia Energy has been approved by the project approval authority. The project funds are self raised by the bidder and bank loans, and the bidder is Inner Mongolia Huifeng Energy Co., Ltd. The bidding agency is Huaneng Tendering Co., Ltd. This project has met the bidding conditions and is now open for bidding for the EPC general contracting project.

2. Project Overview and Bidding Scope

2.1 Project Overview:

The site of the 1 million kilowatt wind storage base guarantee project in Urad Houqi, Bayannur City, Inner Mongolia Autonomous Region is located within the territory of Urad Houqi.

2.2 Scale: The construction capacity for this phase is 1000MW, including 2 220kV booster stations and operation management centers, and 100 wind turbines with a single unit capacity of 10MW. The energy storage system is temporarily designed based on electrochemical shared energy storage, with a storage capacity of 20% and a duration of 2 hours.

2.3 Construction location: Within the territory of Urad Houqi, Bayannur City, Inner Mongolia.

2.4 Construction period requirements: The plan is to start construction on April 15, 2024 (the specific start date shall be notified by the tenderer or supervisor), and the full capacity grid connection conditions will be met by November 16, 2024.

2.5 Scope of bidding:

This project is an EPC general contracting project, and the contractor is responsible for all survey and design, equipment and material procurement, engineering construction, installation and commissioning, testing and acceptance (including government and special acceptance), safety production video monitoring system, smart wind farm design and construction (including full coverage of 5G networks in booster stations and equipment areas), compliance procedures, and external coordination related to the project. Even if it is not specified in the bidding scope, it is actually proven to be a necessary work to ensure the power generation and operation of the project, and it is still within the scope of work that the contractor should undertake. Internally.

The specific bidding scope includes but is not limited to the following content:

(1) Survey and Design: Design and management work for wind farms, maintenance roads, 35kV transmission lines, 220kV substation with few personnel on duty, 220kV substation with personnel on duty and access roads, construction roads, and reactive power topics, including survey and surveying (including test piles and testing, issuing testing reports), micro site selection review, preliminary design, preliminary design estimate, execution estimate, construction drawing design, construction drawing budget, completion drawing publication and settlement, and on-site technical services for equipment. The design must be approved in writing by the employer for implementation. The contractor is required to complete technical disclosure, design representative, dispatch design representatives to the site to solve technical problems related to design during construction, as well as dynamic design work based on site terrain and land acquisition adjustments, and all work related to the full capacity grid connection and completion of this project. The contractor shall not modify the feasibility study or preliminary design plan of the project without authorization. In case of technical changes, the change plan must be approved in writing by the supervisor and the employer before implementation.

(2) Equipment and material supply: The contractor is responsible for the procurement and transportation of complete sets of wind turbine power generation equipment, box transformers, towers, wind turbine foundation anchor plates and bolts (if any), cables (including optical cables), cable terminal (middle) joints, 35kV power collection lines, few person on duty 220kV booster stations, manned 220kV booster stations, SVGs, grid related equipment (including but not limited to wind power prediction equipment, etc.), computer monitoring and protection, communication, communication and measurement equipment required for the entire project. The contractor is responsible for the unloading, secondary transportation (including yard), transportation, storage, management, and handover of all equipment and materials for this bidding project.

(3) Construction and Installation Engineering: The contractor is responsible for all civil engineering, installation, and commissioning work within the scope of the project (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station), and is responsible for cooperating with third-party inspections, tests, and testing commissioned by the tenderer. The contractor is also responsible for individual and system debugging and startup trial operation of the project, acceptance work of local relevant departments, power quality supervision departments, and power grid companies (including project installation and grid connection procedures). The contractor is also responsible for the design, implementation, and acceptance of fire protection, lightning protection, flood prevention and other schemes, as well as other special acceptance work (detailed boundaries are shown in the attached table: Division of Responsibilities between the employer and the contractor). Complete the production and hanging of all equipment identification, safety signs, traffic signs, fire safety signs, and life signs in accordance with national and industry standards, as well as all safety signs and warning lines (including material procurement and compliance with infrastructure and production management standards).

(4) Equipment testing and debugging (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station): including but not limited to fan, box transformer, various specifications of cables, electrical primary equipment system, electrical secondary equipment system, communication system, fire protection system, background monitoring system, video monitoring system installation equipment and protection setting, etc. All equipment and lines within the site are connected to the booster station with "five remote" functions (telemetry, remote signaling, remote adjustment, remote control, and remote viewing) and cooperate with debugging; The performance test of the primary frequency regulation device has passed the power grid acceptance, meeting the remote data transmission requirements of the employer's backend; Third party testing of equipment and materials, calculation of stability control devices and relay protection settings, SVG/performance testing, AVC/AGC performance testing, communication engineering technical services, power quality testing, electromagnetic transient simulation modeling of stations, electromechanical transient simulation modeling, secondary security evaluation, special testing of electrical equipment, network related testing, etc. The grid connection testing services provided meet the relevant requirements of the country, industry, and national power grid.

Responsible for handling grid connection procedures, including but not limited to equipment numbering, line naming, power quality evaluation, protection setting, calibration and acceptance of electricity meters and related equipment, grid connection acceptance of power companies, quality supervision and inspection of power engineering, and obtaining final supervision reports and grid connection agreements, grid connection dispatch agreements, power business licenses, high-voltage power supply and consumption contracts, and purchase and sales contracts. Undertake the review and acceptance related expenses involved in this project.

Responsible for handling administrative permit documents for project commencement, including but not limited to construction land planning permit, construction project planning permit, construction permit, fire protection drawing review and reporting, acceptance, etc;

(5) Defect handling and other work caused by the contractor's responsibility during the warranty period.

(6) Responsible for leveling and handling the transportation roads for large items within the project scope.

(7) Responsible for engineering related work that is not specified in the contract but must be completed in order to complete project construction, acceptance, commissioning, and smooth handover.

(8) Transportation of large equipment, transportation renovation, expansion, reinforcement, widening, clearing of obstacles, road repair (restoration), leasing of secondary transportation sites, and handling of corresponding temporary land use procedures both inside and outside the construction site, and bearing corresponding costs. Road repair (restoration) needs to be carried out according to the original road standards.

(9) Complete the special approval and acceptance procedures for the project as required, as well as other procedures related to the project. (See Appendix: Division of Responsibilities between the Employer and the Contractor)

(10) Responsible for coordinating and arranging the work of connecting to the central control center during the design, procurement, construction, and acceptance stages, ensuring the rationality, completeness, and comprehensiveness of the integration of various systems and equipment in the station into the central control center. Ensure synchronous operation of the station and the central control center.

(11) Responsible for the construction of a smart wind farm for this project, including full coverage of 5G networks.

(12) Responsible for coordinating and incurring costs for local farmers and herdsmen's obstruction of work caused by construction, transportation, and other contracting parties.

(13) Responsible for the construction of a safety production video monitoring system. This project is equipped with a safety production video monitoring system, and it is required that the safety production video monitoring system has the necessary conditions for use before the commencement of the main project (see Annex "Notice on the Configuration of Safety Production Video Monitoring System in New Energy Infrastructure Projects" Xinneng [2023] No. 15), and the data can be uploaded to the Inner Mongolia Energy Group Smart Construction Platform.

(14) The Inner Mongolia Energy Group's smart construction site platform must be used during the project construction process.

Note: In the "Technical Specification Book" of the equipment attached to this bidding document, the tenderer/party refers to the contractor/party of this project, and the bidder/party refers to the subcontractor.

In addition to the clear requirements mentioned above, this includes but is not limited to the survey and design of the wind farm area, supporting 220kV booster stations with few personnel on duty, and manned 220kV booster stations, as well as the procurement and supply of all equipment and materials related to the project, construction of building engineering, installation engineering, project management, commissioning, trial operation, transfer of production, training, acceptance (including stage acceptance, relevant special acceptance, and completion acceptance, etc.), and services during the engineering quality warranty period. The specific bidding scope is detailed in Chapter 6 of the bidding documents, including the requirements of the employer.

4. Inner Mongolia Energy Chayouqian Banner 500000 kilowatt wind and solar power generation project EPC general contracting project bidding announcement

Tender number: HNZB2024-02-3-094

1. Bidding conditions

The EPC general contracting project of the 500000 kilowatt wind and solar power generation project in Inner Mongolia Energy Chayouqian Banner has been approved by the Development and Reform Commission of Ulanqab City, with project code 2312-150926-04-01-849495. The project funds are self raised by the bidder and bank loans, and the bidder is Mengneng New Energy Co., Ltd. in Chahar Right Front Banner. The bidding agency is Huaneng Tendering Co., Ltd. This project has met the bidding conditions and is now open for bidding for the EPC general contracting project.

2. Project Overview and Bidding Scope

2.1 Project Overview

The planned capacity for this project is 500MW, with a wind power installed capacity of 300MW. It is planned to install 30 wind turbines with a single unit capacity of 10MW, and each wind turbine will be equipped with one box type substation; The installed capacity of the photovoltaic system is 200MW, with a total of 61 zones and a design scheme of "block power generation and centralized grid connection". The total installed capacity on the DC side is 239.8578MWp, and a total of 347620 690Wp monocrystalline silicon photovoltaic modules are installed. There are 18 planned 35kV outgoing lines, which will be completed in one phase, including 10 wind farms and 8 photovoltaic lines. The wind capacity of the booster station in this project is 300MW, and the photovoltaic capacity is 200MW; Construct one 220kV booster station, which will be connected to the 220kV side of Tianpishan Substation through a single 220kV line. The final access system plan for this project will be based on the access system review minutes.

2.2 Construction Site

The site of this project is located within the territory of Chayouqian Banner, Ulanqab City, Inner Mongolia, approximately 20km away from the government seat of Chahar Right Front Banner. Chahar Right Wing Front Banner is located in the central southern part of Ulanqab City, Inner Mongolia Autonomous Region, bordering Xinghe County to the east, Fengzhen City to the south, Zhuozi County to the west, Chahar Right Wing Middle Banner to the north, and Ulanqab City in the middle.

2.3 Project Scale: The planned capacity for this phase of the project is 500MW, which will be completed in one go.

2.4 Construction period requirements: The plan is to start construction on April 15, 2024 (the specific start date shall be notified by the tenderer or supervisor), and the full capacity grid connection conditions shall be met before November 16, 2024.

2.5 Scope of bidding:

This project is an EPC general contracting project, and the bidder is responsible for all survey and design, equipment and material procurement, engineering construction, installation and commissioning, testing and acceptance (including government and special acceptance), compliance procedures handling (detailed delineation of boundaries) within the scope of the project bidding (including wind farm, photovoltaic area, booster station, collection line, and on-site and off-site transportation engineering, etc.), as well as external coordination related to the project. Even if it is not specified in the bidding scope, it is actually proven that it is necessary to ensure the operation of the project power generation, and it is still within the scope of work that the bidder should undertake.

Including but not limited to the following content:

(1) Survey and Design: Design and management work for wind farms, photovoltaic areas, maintenance roads, 35kV collection lines, 220kV booster stations, access roads, maintenance roads, construction roads, etc., including survey and mapping, micro site selection review, preliminary design, preliminary design estimate, execution estimate, construction drawing design, construction drawing budget, completion drawing publication and settlement, equipment on-site technical services, etc. The design must be approved in writing by the employer for implementation. The contractor is required to complete technical disclosure, design representative, dispatch design representatives to the site to solve technical problems related to design during construction, as well as dynamic design work based on site terrain and land acquisition adjustments, and all work related to the full capacity grid connection and completion of this project. The contractor shall not modify the feasibility study or preliminary design plan of the project without authorization. In case of technical changes, the change plan must be approved in writing by the supervisor and the employer before implementation.

(2) Equipment and material supply: The contractor is responsible for the procurement and transportation of complete sets of wind turbine power generation equipment, towers, wind turbine foundation anchor plates and bolts (if any), photovoltaic modules and brackets, box (reverse) transformers, cables (including optical cables), cable terminal (middle) joints, 35kV collection lines, 220kV booster station equipment, SVG, grid related equipment (including but not limited to wind power prediction equipment, stability equipment, optical power prediction equipment, OMS, DCCS, OCS, etc.), computer monitoring and protection, communication, communication, and metering equipment required for the entire project. The contractor is responsible for the unloading, secondary transportation (including yard), and on-site and off-site transportation of all equipment and materials for this bidding project. Transportation, storage, management, and handover work.

(3) Construction and Installation Engineering: The contractor is responsible for all civil engineering, installation, and commissioning work within the scope of the project (excluding special testing of the booster station, subsystem debugging of the booster station, and whole set startup debugging of the booster station), responsible for individual and system debugging and startup trial operation of the project, responsible for acceptance work of relevant local departments, power quality supervision departments, and power grid companies (including project installation and grid connection procedures), responsible for the implementation of environmental protection measures, water conservation measures, occupational assessment and safety assessment measures, environmental protection and environmental impact assessment, fire protection, lightning protection, flood prevention and other scheme design, implementation, and acceptance work, and other special acceptance work (detailed boundaries are shown in the attached table: Division of Responsibilities between the employer and the contractor). Complete the production and hanging of all equipment identification, safety signs, traffic signs, fire safety signs, life signs, and other signs in accordance with national and industry standards, as well as all safety signs and warning lines (including material procurement and compliance with infrastructure and production management standards), and a safety production video monitoring system.

(4) Equipment testing and debugging (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station): including but not limited to fan, box transformer, various specifications of cables, electrical primary equipment system, electrical secondary equipment system, communication system, fire protection system, background monitoring system, video monitoring system installation equipment and protection setting, etc. All equipment and lines within the site are connected to the booster station with "five remote" functions (telemetry, remote signaling, remote adjustment, remote control, and remote viewing) and cooperate with debugging; The performance test of the primary frequency regulation device has passed the power grid acceptance, meeting the remote data transmission requirements of the employer's backend; Third party testing of equipment, calculation of stability control devices and relay protection settings, SVG/phase-shifting camera performance testing, AVC/AGC performance testing, communication engineering technical services, power quality testing, electromagnetic transient simulation modeling of stations, electromechanical transient simulation modeling, secondary security protection evaluation, special testing of electrical equipment, network related testing, etc. The grid connection testing services provided meet the relevant requirements of the country, industry, and national power grid.

Responsible for handling grid connection procedures, including but not limited to equipment numbering, line naming, power quality calculation, protection setting, calibration and acceptance of electricity meters and related equipment, grid connection acceptance of power companies, quality supervision and inspection of power engineering, and obtaining final supervision reports and grid connection agreements, grid connection dispatch agreements, power business licenses, and purchase and sales contracts, and bearing the costs of review, acceptance, and supervision related to this project.

Responsible for handling administrative permit documents for project commencement, including but not limited to construction land planning permit, construction project planning permit, construction permit, fire protection drawing review and reporting, etc;

(5) Defect handling and other work caused by the contractor's responsibility during the warranty period.

(6) Responsible for leveling and handling the transportation roads for large items within the project scope.

(7) Responsible for engineering related work that is not specified in the contract but must be completed in order to complete project construction, acceptance, commissioning, and smooth handover.

(8) Transportation renovation, expansion, reinforcement, widening, clearing of obstacles, road repair (restoration), leasing of secondary transportation sites, and handling of corresponding temporary land use procedures required for the transportation of large equipment both inside and outside the site, and corresponding expenses shall be borne.

(9) Complete the special approval and acceptance procedures for the project as required, as well as other procedures related to the project. (See Appendix: Division of Responsibilities between the Employer and the Contractor)

(10) Responsible for coordinating and arranging the work of connecting to the central control center during the design, procurement, construction, and acceptance stages, ensuring the rationality, completeness, and comprehensiveness of the integration of various systems and equipment in the station into the central control center. Ensure synchronous operation of the station and the central control center.

(11) This project is equipped with a safety production video monitoring system. It is required that the safety production video monitoring system has the necessary conditions for use before the commencement of the main project (see Annex "Notice on the Configuration of Safety Production Video Monitoring System for New Energy Infrastructure Projects" Xinneng [2023] No. 15), and the data can be uploaded to the Inner Mongolia Energy Group Smart Construction Platform. Responsible for the construction of the smart power station for this project, including full coverage of 5G networks.

(12) The Inner Mongolia Energy Group's smart construction site platform must be used during the project construction process.

(13) Responsible for handling real estate property rights, and government payments such as property ownership certificate fees are the responsibility of the tenderer.

(14) Responsible for engineering related work that is not specified in the contract but must be completed in order to complete project construction, acceptance, commissioning, and smooth handover.

Note: In the "Technical Specification Book" of the equipment attached to this bidding document, the tenderer/party refers to the contractor/party of this project, and the bidder/party refers to the subcontractor.

In addition to the clear requirements mentioned above, this includes but is not limited to the survey and design of wind farm areas, 220kV booster stations, 35kV collection lines, as well as the procurement and supply of all equipment and materials related to the project, construction and installation engineering, project management, commissioning, trial operation, transfer of production, training, acceptance (including stage acceptance, relevant special acceptance and completion acceptance, etc.), and services during the engineering quality warranty period. The specific bidding scope is detailed in Chapter 6 of the bidding documents, Employer's Requirements.

5. Bid Announcement for EPC General Contracting Project of One Million Kilowatt Wind Storage Base Project in Tuquan County, Inner Mongolia Energy

Tender number: HNZB2024-02-3-093

1. Bidding conditions

The EPC general contracting project of the million kilowatt wind storage base project in Tuquan County, Inner Mongolia Energy has been approved by the project approval authority. The project funds are self raised by the bidder and bank loans, and the bidder is Inner Mongolia Mengneng Liquan Energy Co., Ltd. The bidding agency is Huaneng Tendering Co., Ltd. This project has met the bidding conditions and is now open for bidding.

2. Project Overview and Bidding Scope

2.1 Project Overview:

The site of the million kilowatt wind storage base project in Tuquan County, Inner Mongolia Energy is located in the area of Liuhu Town and Baoshi Town in Tuquan County, Xing'an League, Inner Mongolia Autonomous Region. The center coordinates of the address are longitude 121.280 ° and latitude 45.64 °, with the terrain mainly consisting of hills and plains. The plains are mostly basic farmland, and the elevation of the site is between 400m and 750m. There are G111 National Highway, G334 National Highway, and multiple township roads near the site, making external transportation more convenient.

The million kilowatt wind storage base project in Tuquan County, Inner Mongolia Energy has a planned wind farm capacity of 1000MW, with an installed capacity of 1000MW in this phase. It is proposed to use 100 wind turbines with a single unit capacity of 10MW.

The two newly built booster stations in this project (one is a 220KV~500KV booster station, designed according to the principle of "manned, manned", and the other is a 220KV booster station designed according to the principle of "unmanned, unmanned"). According to the current situation and development plan of power transmission and transformation around the project, it is planned to connect to the Pingchuan 500KV substation as the access system station for this project. The final system access method shall be subject to the access approval.

2.2 Project scale: The planned construction capacity is 1 million kilowatts, with the construction of one 220KV~500KV booster station and one 220KV booster station. This phase will be completed in one go.

2.3 Construction location: Within the territory of Tuquan County, Xing'an League, Inner Mongolia Autonomous Region.

2.4 Construction period requirements: The plan is to start construction on April 15, 2024 (the start refers to the pouring of the first tank of concrete for the fan foundation, and the specific start date is subject to the notice of the tenderer or supervisor), and to have full capacity grid connection conditions before November 16, 2024.

2.5 Scope of bidding:

This project is an EPC general contracting project, and the contractor is responsible for the scope of engineering bidding, including but not limited to wind farms, 220KV~500KV booster stations, 220KV booster stations, 220KV interconnection lines and access roads between two booster stations, all survey and design of construction roads, equipment and material procurement, engineering construction, installation and commissioning, testing and acceptance (including government and special acceptance), smart wind farm design and construction, full coverage of 5G network (including booster stations and equipment areas), temporary land acquisition, vegetation restoration, compliance procedures handling (see the responsibility division table between the employer and the contractor), and external coordination related to the project. Even if it is not specified in the bidding scope, it has been proven to be necessary to ensure the power generation operation of the project. The work is still within the scope of work that the contractor should undertake, including but not limited to the following:

(1) Survey and Design: Design and management work for wind farm area, maintenance roads, 35KV collection lines, 220KV~500KV boosting stations, 220KV boosting stations, 220KV connecting lines between two boosting stations and entrance roads, construction roads, including survey and surveying (including test piles and testing, issuing testing reports), micro site selection review, preliminary design, preliminary design estimate, execution estimate, construction drawing design, construction drawing budget, publication and organization of completion drawings, completion settlement, and on-site technical services for equipment, etc. The design needs to be approved in writing by the employer for implementation. The contractor is required to complete technical disclosure, design representative, dispatch design representatives to the site to solve technical problems related to design during construction, as well as dynamic design work based on site terrain and land acquisition adjustments, and all work related to the full capacity grid connection and completion of this project. The contractor shall not modify the feasibility study or preliminary design plan of the project without authorization. In case of technical changes, the change plan must be approved in writing by the supervisor and the employer before implementation.

(2) Equipment and material supply: The contractor is responsible for the procurement and transportation of complete sets of wind turbine power generation equipment, box transformers, towers, wind turbine foundation anchor bolts, cables (including optical cables), cable terminal (middle) joints, 35KV collection lines, 220KV~500KV booster stations, SVGs, phase-shifting cameras, network related equipment (including but not limited to wind power prediction equipment, etc.), computer monitoring and protection, communication, communication, and measurement equipment required for the entire project. The contractor is responsible for the unloading, secondary transportation (including yard), transportation, storage, management, and handover of all equipment and materials (including those provided by the employer) for this bidding project.

(3) Construction and Installation Engineering: The contractor is responsible for all civil engineering, installation, and commissioning work within the scope of the project (excluding special testing of the booster station, subsystem debugging of the booster station, and whole set startup debugging of the booster station), and is responsible for cooperating with a third party commissioned by the tenderer to carry out various inspections, tests, and tests of the project. The contractor is responsible for individual and system debugging and startup trial operation of the project, and is responsible for the acceptance work of local relevant departments, power quality supervision departments, and power grid companies (including project installation and grid connection procedures). The contractor is responsible for the implementation of environmental protection measures, water conservation measures, occupational assessment and safety assessment measures, environmental protection and environmental impact assessment, fire protection, lightning protection, flood prevention and other scheme design, implementation, and acceptance, and other special acceptance work (detailed boundaries are shown in the attached table: the employer and the contractor). Responsibility division table). Complete the production and hanging of equipment signage, safety signs, traffic signs, fire signs, and life signs in accordance with national and industry standards, as well as all safety signs and warning lines (including material procurement and compliance with infrastructure and production management standards).

(4) Equipment testing and debugging (excluding special testing of the booster station, subsystem debugging of the booster station, and overall startup debugging of the booster station): including but not limited to the installation and protection setting of fans, box transformers, various specifications of cables, electrical primary equipment systems, electrical secondary equipment systems, communication systems, fire protection systems, background monitoring systems, and video monitoring systems. All equipment and lines within the site are connected to the booster station with "five remote" functions (telemetry, remote signaling, remote adjustment, remote control, and remote viewing) and cooperate with debugging; The performance test of the primary frequency regulation device has passed the power grid acceptance, meeting the remote data transmission requirements of the employer's backend; Third party testing of equipment, calculation of stability control devices and relay protection settings, SVG performance testing, phase-shifting camera performance testing, AVC/AGC performance testing, communication engineering technical services, power quality testing, electromagnetic transient modeling of stations, electromechanical transient simulation modeling, secondary security protection evaluation, special testing of electrical equipment, network related testing, etc. The grid connection testing services provided meet the relevant requirements of the country, industry, and national power grid.

Responsible for handling grid connection procedures, including but not limited to equipment numbering, line naming, power quality calculation, protection setting, calibration and acceptance of electricity meters and related equipment, grid connection acceptance of power companies, quality supervision and inspection of power engineering, and obtaining final supervision reports, grid connection agreements, grid connection scheduling agreements, power generation business licenses, and purchase and sales contracts, and bearing the review and acceptance related costs involved in this project.

Responsible for handling administrative permit documents for project commencement, including but not limited to construction land planning permit, construction project planning permit, construction permit, fire protection drawing review and reporting, etc;

(5) Defect handling and other work caused by the contractor's responsibility during the warranty period.

(6) Responsible for leveling and handling the transportation roads for large items within the project scope.

(7) Responsible for engineering related work that is not specified in the contract but must be completed in order to complete project construction, acceptance, commissioning, and smooth handover.

(8) During the transportation and construction of large equipment, the transportation renovation, expansion, reinforcement, widening, clearing of obstacles, road repair (restoration), leasing of secondary transportation sites, and handling of corresponding temporary land use procedures both inside and outside the site shall be undertaken, and corresponding costs shall be borne.

(9) Complete the special approval and acceptance procedures for the project as required, as well as other procedures related to the project. (See Appendix: Division of Responsibilities between the Employer and the Contractor).

(10) Responsible for coordinating and arranging the work of connecting to the central control center during the design, procurement, construction, and acceptance stages, ensuring the rationality, completeness, and comprehensiveness of the integration of various systems and equipment in the station into the central control center. Ensure synchronous operation of the station and the central control center.

(11) Responsible for the design and construction of smart wind farms, full coverage of 5G networks (including booster stations and equipment areas)

(12) This project is equipped with a safety production video monitoring system. It is required that the safety production video monitoring system has the necessary conditions for use before the commencement of the main project (see Annex "Notice on the Configuration of Safety Production Video Monitoring System for New Energy Infrastructure Projects" Xinneng [2023] No. 15), and the data can be uploaded to the Inner Mongolia Energy Group Smart Construction Platform.

Note: In the technical specifications of the equipment attached to this bidding document, the bidder/party refers to the subcontractor, while the bidder/party refers to the contractor/party of this project.

In addition to the clear requirements mentioned above, this includes but is not limited to the survey and design of wind farms, 220KV~500KV booster stations, 220KV booster stations, 220KV interconnection lines and access roads between two booster stations, 35KV collection lines, as well as the procurement and supply of all equipment and materials related to the project, supervision and testing, construction and installation engineering construction, project management, debugging, trial operation, transfer of production, training, acceptance (including stage acceptance, relevant special acceptance and completion acceptance), and services during the engineering quality warranty period. The specific bidding scope is detailed in Chapter 6 of the bidding documents, including the requirements of the employer.

*Some documents are sourced from the internet. If there is any infringement, please contact the website to delete them

- ● Jinhai Corporation and Zhongentropy Technology signed a strategic cooperation agreement[2025-11-03]

- ● Building a Strong Security Line and Guarding Safety During the Double Festival, Jinhai Shares held a special meeting on safety production work before the National Day holiday[2025-09-30]

- ● Jinhai Corporation and Oriental Enterprise Innovation and Development Center visited Shanghai Lu Mingxing Guang Intelligent Technology Co., Ltd. for inspection and exchange[2025-09-19]

- ● Good news! Jinhai Group Jiangsu Company won the Shanghai Science and Technology Progress Award[2025-08-29]

- ● Jinhai Corporation held the 2025 Summer Safety Work Conference and the First Half of the Year Safety Work Summary Meeting[2025-07-16]

- ● [Recruitment] Jinhai Stock Recruitment: 1 Technical Quality Engineer (working language: English)[2025-07-15]

- ● Jinhai Corporation and China Construction Eighth Engineering Division General Contracting Company have reached a strategic cooperation to jointly promote the innovative development of the wind power industry[2025-07-12]

- ● The "New Thought Volunteer Propaganda Team" of the Yancheng Municipal Party School and the Funing County Party School came to the Jinhai Lecture Hall to give a lecture on "Deeply Studying and Implementing the Spirit of the Central Eight point Regulation, Persistently Strengthening the Construction of the Party's Work Style"[2025-06-20]

- ● Jinhai Group and Shanghai Electric Wind Power Group signed a strategic cooperation agreement[2025-06-05]

- ● Jinhai Group Jiangsu Branch and Jiangsu Funing Development Zone First Party Branch Carry out Party Building and Co construction Activities[2025-06-05]