Segmented straight tower prestressed concrete tower | Inner Mongolia Jinhai New Energy Technology Co., Ltd

With the continuous increase in the proportion of clean energy generation and the development of wind power resources in low wind speed areas, wind turbines are showing a clear trend towards large-scale operation: larger installed capacity, larger wheel diameter, and higher hub height. Large scale wind turbines lead to a several fold increase in internal forces of the supporting tower, and the height of the tower increases due to the lifting of the hub, making vibration control more difficult and often causing significant losses in power generation. It is of great significance to find solutions that meet the requirements of wind turbines for the bearing capacity and stiffness of supporting towers.

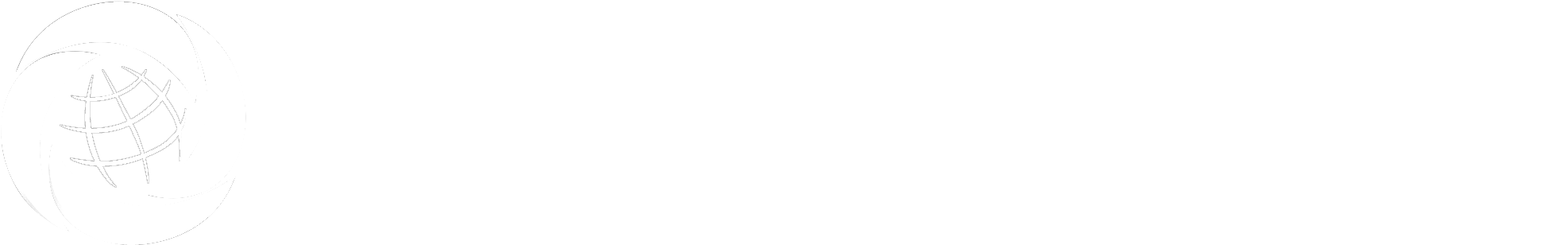

Realistic scene of grid connected project 1

The Jinhai "segmented straight tower prestressed concrete tower" emerged in the above context. Compared to traditional steel structure towers, concrete towers have obvious advantages: using concrete as the main material of the tower, it has greater bearing capacity and stiffness compared to flexible steel towers; The longitudinal prestressing technology is used to achieve the connection of cylinder sections, which are produced by factory prefabrication, with almost no on-site wet work or fastener connections; The concrete has good durability, and the maintenance and operation costs of the tower in the later stage are greatly reduced.

As a long-standing manufacturer of wind power support structure components and one of the earliest practitioners of hybrid towers in China, Jinhai's proposed "segmented straight tower prestressed concrete tower" has both the common advantages of the aforementioned hybrid towers and typical Jinhai characteristics:

The tower type adopts a combination of straight tower and centralized variable diameter tower, which can flexibly adjust the bearing capacity and natural frequency of the tower by adjusting the variable diameter position, matching the requirements of various aircraft models for clearance, vibration control, and bearing capacity;

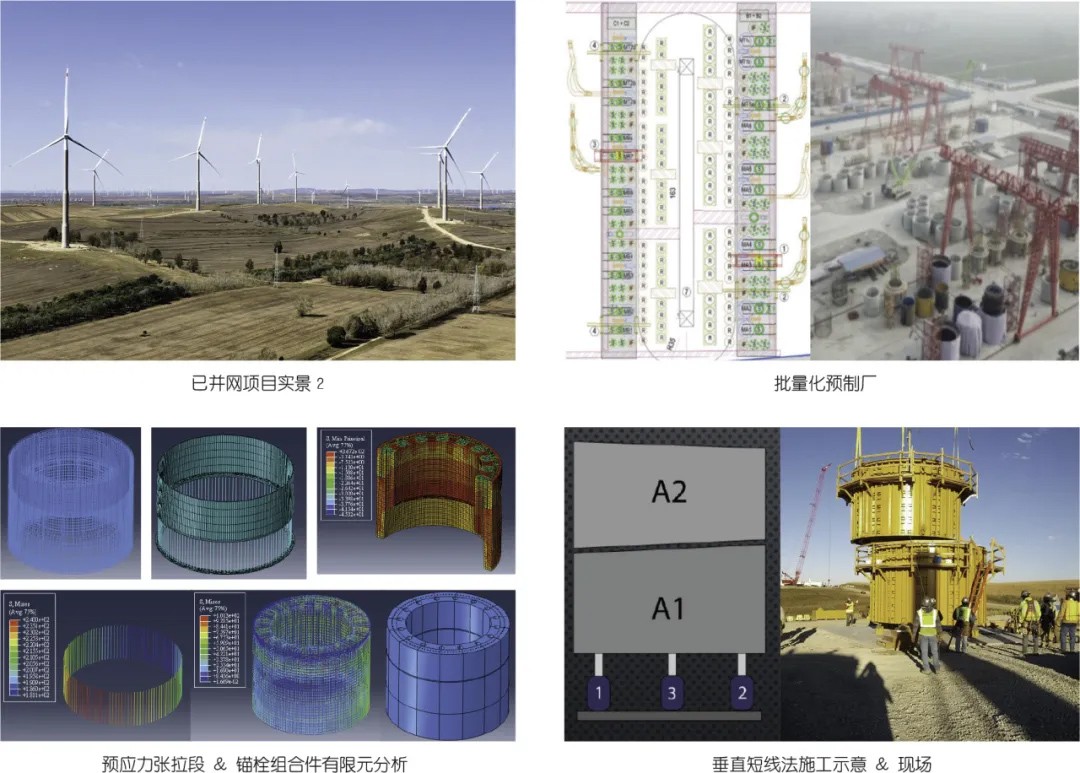

The use of prestressed anchor bolt assemblies to achieve the conversion connection between the upper steel tower and the lower mixed tower, as a patented product of Jinhai, has been applied to the connection between steel towers and foundations for nearly 20 years. It is safe, reliable, and has good fatigue resistance performance;

The vertical short line method is used for tower prefabrication production, effectively ensuring the matching of the interface between adjacent concrete segments. The errors of the constructed mixed tower segments can be eliminated through template correction;

The use of prestressed segmented tensioning technology effectively improves the utilization rate of steel strand materials and significantly enhances the safety during the construction process of the mixed tower section.

Since the successful installation of the first self-developed 130 meter wind power hybrid tower in Jiangsu in 2017, Jinhai Group has been deeply involved in the research and application of wind power hybrid towers for seven years, and has established close cooperative relationships with mainstream domestic wind turbine manufacturers. The number of cooperative wind turbine manufacturers has exceeded ten, leaving multiple pioneering footprints in the development history of wind power hybrid towers in China. The company has successfully provided product services for multiple projects of five major and six small power central enterprises, and has delivered nearly a thousand wind turbine concrete towers for grid connected operation. Jinhai Group's hybrid towers are distributed in wind power projects in Jiangsu, Henan, Hebei, Shandong, Gansu, Anhui, Hubei, Heilongjiang, Jilin, Tianjin, Yunnan, Shanxi, Guizhou and other places. Chang'an has been fully connected to the grid for seven years. Looking ahead to the future, the company's mature modular hybrid tower design platform products will rapidly expand to 10MW+onshore wind turbine applications, with hub heights reaching up to 180 meters or even exceeding 200 meters. With ultra-low electricity costs, reliability, and intelligent delivery, Jinhai Group will provide efficient wind power tower solutions for the global zero carbon transformation.

Recently, Jinhai Group has collaborated with leading domestic wind turbine manufacturers to complete the integrated design of 185m hub height and ≥ 8.5MW high-power wind turbines with steel-concrete tower structures in multiple projects. By optimizing the combination of a unique straight tower and a centralized variable diameter tower, the tower rotor blade tip diameter, vibration frequency, and bearing capacity can be flexibly adjusted, successfully matching various requirements such as safe clearance, vibration control, and bearing safety throughout the operating life cycle of wind turbines. The segmented tensioning technology of steel strands used in the design process has successfully expanded the height of the mixed tower section of the tower to over 160m; Segmented tensioning technology can not only improve the utilization efficiency of steel strand materials, but also enhance the safety during the construction process of mixed tower sections, achieving the goal of balancing cost and tower safety. The successful completion of this batch of project designs has greatly expanded the application scope of steel-concrete tower frames, providing more high-quality options for the development of wind power resources in areas with low wind speeds and high shear rates.

Special thanks:

Inner Mongolia Jinhai New Energy Technology Co., Ltd

Provide technical support and publishing authorization for this article

Reference materials:

*Some documents are sourced from the internet. If there is any infringement, please contact the website to delete them

- ● The 10th Workers' Sports Meeting of Jinhai Group was successfully held[2025-11-28]

- ● Jinhai Group held a seminar on studying and implementing the spirit of the Fourth Plenary Session of the 20th Central Committee of the Communist Party of China[2025-11-17]

- ● Jinhai Group holds a symposium for new employees in 2025[2025-11-14]

- ● Jinhai Corporation and Zhongentropy Technology signed a strategic cooperation agreement[2025-11-03]

- ● Building a Strong Security Line and Guarding Safety During the Double Festival, Jinhai Shares held a special meeting on safety production work before the National Day holiday[2025-09-30]

- ● Jinhai Corporation and Oriental Enterprise Innovation and Development Center visited Shanghai Lu Mingxing Guang Intelligent Technology Co., Ltd. for inspection and exchange[2025-09-19]

- ● Good news! Jinhai Group Jiangsu Company won the Shanghai Science and Technology Progress Award[2025-08-29]

- ● Jinhai Corporation held the 2025 Summer Safety Work Conference and the First Half of the Year Safety Work Summary Meeting[2025-07-16]

- ● [Recruitment] Jinhai Stock Recruitment: 1 Technical Quality Engineer (working language: English)[2025-07-15]

- ● Jinhai Corporation and China Construction Eighth Engineering Division General Contracting Company have reached a strategic cooperation to jointly promote the innovative development of the wind power industry[2025-07-12]