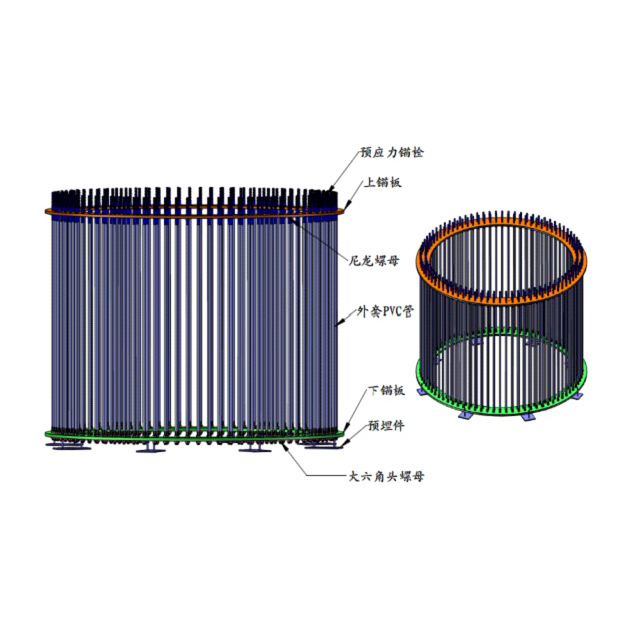

Reverse balance flange

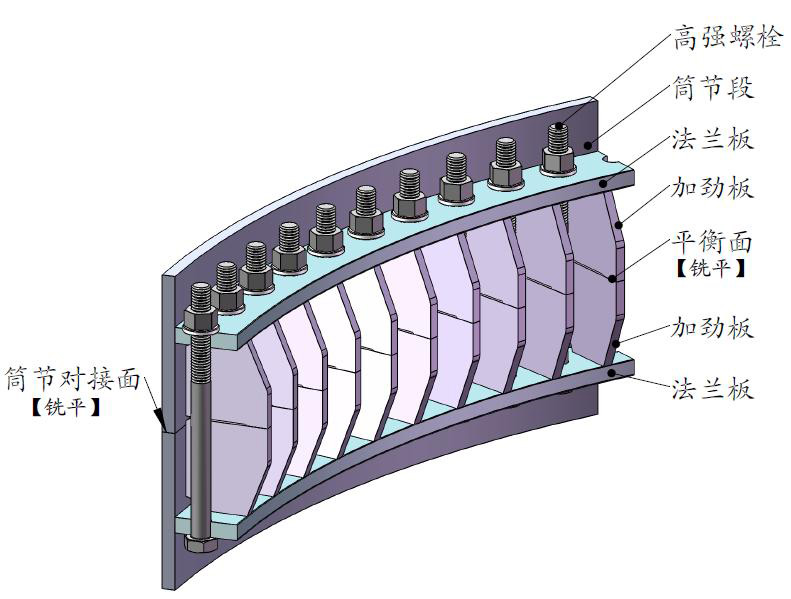

Our company has independent intellectual property rights for our product - reverse balance flange, which is a national key new product jointly issued by the Ministry of Science and Technology, the Ministry of Environmental Protection, the Ministry of Commerce, and the General Administration of Quality Supervision, Inspection and Quarantine. Reverse balance flange is mainly used for connecting the tower body of the wind turbine. A "balance surface" is set in the center of the tower by the "reverse" flange plate and stiffener plate. Under the action of cyclic wind load, the "balance surface" can basically offset the tensile stress torque acting on the cylinder section through the stiffener plate. The required connecting bolts have a small diameter, appropriate length, and can precisely control the pre tension value, thereby achieving fatigue resistance and maintenance free functions. The use of reverse balance flanges as connectors can ensure that the bending stiffness of the tower remains unchanged under cyclic dynamic loads, greatly improving the stress on the fan drum. The reverse balance flange has a novel structure and reasonable design, reducing steel consumption by more than 50%, effectively solving the high energy consumption and high pollution problems in the traditional flange manufacturing process.

Unlike ordinary flanges, the reverse balance flange stiffening plate is located in the front and the flange plate is located at the back. Therefore, without thickening the flange plate, only increasing the stiffening plate can increase the flange stiffness. At the same time, increasing the stiffening plate allows for bolt growth, which is conducive to accurately applying bolt pre tension. By adjusting the size of the flange, the bending moment generated by the pressure on the "balance surface" of the stiffening plate at weld A (the weld between the stiffening plate and the cylinder wall) is balanced with the bending moment generated by the bolt pre tension at weld A, thereby reducing the bending moment on weld A and the size of the stiffening plate.

Compared with forged flanges, reverse balance flanges have changed the connection technology of the fan tower, and have the following advantages: the bolt operation spacing is not affected by the stiffening plate, the bolt arrangement is fine and compact, and the flange plate is thinner; Reduce steel by more than 10%, while reducing the unit price per ton of finished flange by 20%; Reduced end milling processing surface, low production energy consumption, and low cost; The welding seam between the reverse balance flange and the tower is a wall welding seam of the same material as other welding seams on the tower, which is easy to ensure welding quality; Less welding quantity, convenient welding; It can effectively improve the stress condition of the flange and cylinder wall weld seam, and solve the defect problem of welding heat affected zone.